Among the top ten companies in the world in terms of production and sales of power batteries, Chinese companies account for 6 places, with significant growth in scale and profits

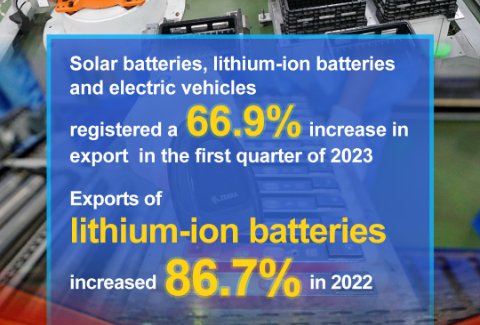

According to the China Association of Automobile Manufacturers, from January to March, China's cumulative production of power batteries reached 130.0 gigawatts per hour, a year-on-year increase of 26.3%; The cumulative sales volume was 108.5 GWh, a year-on-year increase of 66.8%; Among them, the cumulative export is 25.8 GWh.

In 2022, China's sales of new energy vehicle supporting batteries reached nearly 300 GWh, ranking first in the world for 8 consecutive years. Among the top ten enterprises in the global production and sales of power batteries, Chinese enterprises account for 6 positions, and their competitiveness and brand effect are gradually emerging.

Under the guidance of the "dual carbon" goal, China's power battery materials and new technology applications continue to make breakthroughs, forming the most comprehensive and largest power battery industry system in the global industry chain from material research and development, battery production, recycling to equipment support, and serving the construction of ecological civilization with high-quality development of the industry, boosting the great cause of Chinese path to modernization to go deeper and deeper.

01. Both scale and profit have increased significantly

With the support of relevant policies, China's new energy vehicle and power battery industries have achieved corresponding growth in efficiency while expanding in scale. In 2022, the total production of power batteries in China reached 545.9 gigawatts, an increase of 148.5% year-on-year; The total sales volume was 465.5 GWh, a year-on-year increase of 150.3%; The total installed capacity was 294.6 GWh, a year-on-year increase of 90.7%.

In the first quarter of this year, the production and sales of power batteries nationwide increased significantly, with a cumulative production of 45.7 gigawatts of ter batteries, accounting for 35.1% of the total production, a year-on-year increase of 15.1%; The cumulative sales volume is 44.7 GWh, accounting for 41.3% of the total sales volume, with a year-on-year increase of 62.5%; Accumulated exports amounted to 18.7 GWh, accounting for 72.6% of the total export volume. The cumulative output of Lithium iron phosphate batteries is 84.1 GW/h, accounting for 64.7% of the total output, with a year-on-year growth of 33.4%; The cumulative sales volume is 63.6 GWh, accounting for 58.6% of the total sales volume, with a year-on-year increase of 70.2%; The cumulative export volume is 7.0 GWh, accounting for 27.2% of the total export volume.

Since the beginning of the year, with the favorable effect of the decline in raw material prices, the production cost of batteries has also decreased. According to relevant statistics, 29 lithium battery companies listed in Shanghai and Shenzhen achieved a total net profit of 17.851 billion yuan in the first quarter, with an average net profit of 616 million yuan, of which 22 achieved profitability. The total revenue of the above-mentioned enterprises in 2022 is 1128.316 billion yuan, with an average revenue of 38.907 billion yuan; Among them, there are 16 companies with revenue exceeding 10 billion yuan; There are 26 companies with positive year-on-year revenue growth, accounting for nearly 90%.

"China has more than 13 million new energy vehicles, accounting for more than half of the world's total. Sun Shigang, an academician of the CAS Member, said that driven by the goal of "dual carbon", the development speed will be faster.

Relevant parties believe that China's production of new energy vehicles is expected to reach 9 million units this year. Driven by this, China's power battery industry still has enormous development potential.

According to predictions, by 2025, the compound annual growth rate of China's automotive power battery market will reach 29%; The shipment volume of power batteries for new energy vehicles will reach 470 GWh, with a compound annual growth rate of 42.5%.

02. Improved range and lifespan

While the market size is growing rapidly, the pace of technological upgrading in China's power battery industry is also accelerating.The high-speed development of Alternative fuel vehicle has put forward higher and higher requirements for power cells and fuel cells. Sun Shigang believes that this requirement is comprehensive, including energy density, power density, safety, service life, extreme environmental applications and cost reduction.

Fan Wenguang, Vice President of Shenzhen Bike Power Battery Co., Ltd., also stated that people's focus on electric vehicles is often related to power batteries, such as safety, range, charging capacity, and so on.

"Range anxiety" has been puzzling new energy vehicle owners. Fan Wenguang admitted that currently electric vehicles can basically meet the needs of commuting within the city, but it is still difficult to meet long-distance travel between cities, especially in winter when the range is also discounted in low temperatures, which creates obstacles for people to choose electric vehicles.

Zhang Xiaocong is confident in his battery technology: "At present, those equipped with our Lithium iron phosphate battery can achieve a 700 km endurance, and those equipped with the medium nickel battery can achieve a 1000 km endurance.

Wang Yu, chairman of Funeng Technology (Ganzhou) Co., Ltd., believes that the endurance of electric vehicles must be improved from "yes" to "good". "For example, the actual endurance of a vehicle with a nominal mileage of 500 kilometers is about 350-400 kilometers, which will be worse in winter, especially for Lithium iron phosphate batteries, which have only 50% or 60% of the endurance.

Of course, power battery technology is not the best, only better.

On January 18th, at a press conference held by the State Administration for Industry and Information Technology, Tian Yulong, a member of the Party Group, Chief Engineer, and spokesperson of the Ministry of Industry and Information Technology, announced that in 2022, China's mass production of power batteries will have a single energy density of 300 watt hours per kilogram, which is at the international leading level.

For power batteries, the selection of positive and negative electrode materials determines the upper limit of battery energy density. "Zhou Lisha, co-founder and CEO of Anhui Mengwei New Energy Technology Co., Ltd., believes that from the perspective of high specific energy power battery technology, The upgrade direction of positive electrode materials is from NCM 622 to NCM 811, and then to the current 9 series, developing towards high nickel and lithium rich manganese based; The development direction of the negative electrode is from graphite to silicon carbon, and then the lithium metal. In the future, it will achieve lighter ultra-thin lithium metal, and lithium metal batteries are the ultimate solution for high specific energy batteries.

Xiao Chengwei, a researcher at the 18th Research Institute of China Electronics Technology Group Corporation, said that for lithium rich manganese based cathode materials, 250 mAh/g can now be basically achieved, and matched with silicon carbon can make the battery energy density reach 400 watt hours/kg or more. The Lithium iron phosphate liquid technology roadmap also shows a very high level. Taking the Lithium iron phosphate blade battery with a capacity of 150 Ah as an example, the energy density of a single battery can reach 190 watt hours / kg, and 156 watt hours / kg after integration.

According to Xie Qiu, senior vice president of China Innovation Aviation Technology Group Co., Ltd., the One Stop technology launched by the company can significantly improve the space utilization rate of the cell in the battery pack, and can increase the energy density of the Lithium iron phosphate battery pack to 153 watt hours/kg. If it is equipped with high manganese lithium iron, the energy density of the battery pack can be increased to 180 watt hours / kg.

On April 19, CATL officially released the innovative cutting-edge battery technology - condensed battery. The individual energy density of this battery can even reach up to 500 watt hours/kg, achieving a combination of high specific energy and high safety.

In addition to the range, the battery lifespan and battery decay of batteries are also of great concern to electric vehicle consumers. Under conventional voltage, lithium rich manganese based materials have the best cycling stability among all commercially available positive electrode materials, with a room temperature cycle that does not decay for 2300 weeks and a charge discharge retention rate of 88% for 1700 weeks at 45 degrees Celsius.Hu Wei, Executive Vice General Manager of Ningxia Hanyao Lithium Technology Co., Ltd.

Huang Xiangdong, Chairman and CTO of Guangzhou Juwan Technology Research Co., Ltd., stated that the ultra fast charging battery developed by Juwan Technology Research has a driving range of over 750000 kilometers, and its capacity retention rate is still at the level of 94% -91%. Moreover, all cycles are under the condition of ultra fast charging. In addition, the company's President Pei Feng stated that the cycle life of the batteries is also very important. The commercial vehicle power battery launched by the company can achieve ultra fast charging and normal discharge 2000-3000 times, with a very good cycle life.

03. Fundamental improvement in safety

Safety is an unavoidable topic. China has successively issued documents such as "Safety Requirements and Test Methods for Power Batteries Used in Electric Vehicles" (GB/T 31485-2015) and "Safety Requirements for Power Batteries Used in Electric Vehicles" (GB 38031-2020), proposing detailed requirements for the safety of power batteries.

After so many years of effort, it can be said that the safety of automotive power batteries has fundamentally changed. "Liu Jincheng, Chairman of Huizhou Yiwei Lithium Energy Co., Ltd., is optimistic. He stated that Yiwei Lithium Energy has delivered batteries for almost 100000 vehicles, which are fully guaranteed in terms of system safety.

Fan Wenguang also stated that the safety of batteries can be improved through their appearance and structure. Large cylindrical batteries can fully control safety risks,maintaining a zero heat diffusion state, so that electric vehicles are no longer linked to words such as'fire 'and'explosion.

Xiao Chengwei introduced that his employer has done a lot of work in battery thermal diffusion suppression technology, such as adopting flame-retardant microcapsule technology and achieving high-temperature flue gas directional drainage to enhance the thermal diffusion suppression of batteries; In addition, big data is also used to predict battery safety risks.

In order to improve the safety of the battery, Anhui Mengwei New Energy Technology Co., Ltd. has adopted lithium anode protection, combined with functional electrolyte with flame retardancy, combined with composite current collection and other technologies to inhibit the growth of lithium dendrites, which can effectively control the risk of thermal runaway and thermal diffusion. Zhou Lisha introduced that the company's products can already pass safety standards such as acupuncture, high and low temperatures, and short circuits.

The underlying logic of developing power batteries is still safety,Xie Qiu remains cautious about power battery safety issues. He stated that although battery technology has made significant progress, the safety level still needs to be improved.

04. Joint layout of upstream and downstream

Although China ranks first in the power battery production capacity and new energy vehicle market, it is not enough to ensure that the entire industry chain is free from worries. Data shows that China's lithium resource reserves only account for 7% of the global total. There is uncertainty in the supply of lithium resources.

The first challenge for the development of the power battery industry is resources. There are certain difficulties in extracting lithium in China, "said Sun Shigang. Although China has the world's largest production of lithium batteries, 70% of its lithium resources rely on imports.

In the past, emphasizing technology, quality, and cost was enough, but last year many domestic enterprises were investing in the supply chain to ensure the supply of upstream resources, "said Liang Rui, Vice President of Xinwangda Electronics Co., Ltd.

Faced with scarce lithium resources, battery manufacturers are working together to seize the mines. The CATL started early and invested in the North American lithium industry, Neo Lithium, a Canadian mining enterprise, Pilbara Minerals, an Australian mining enterprise, etc.

Ruipu Lanjun Company is a new company established by Qingshan Industry. Qingshan Industry is the global nickel king, and we have a layout of the entire industry chain from upstream to downstream. Zhang Xiaocong said that Qingshan Industry's investment projects involve lithium, nickel, and cobalt mines, which are very rich in minerals.

Battery recycling downstream of the industrial chain is also a wind driven and water driven industry.

From the perspective of industrial development, the annual growth rate of power batteries is over 35%, which will inevitably lead to a large number of battery retirement issues, including defective products generated in the production process. Proper recycling and utilization are related to the sustainable development of the entire new energy industry and the realization of low-carbon development. "Zhang Yuping, Deputy General Manager of Greenway Co., Ltd., gave another reflection on the development of the power battery industry.

The New Energy Vehicle Industry Development Plan (2021-2035) requires improving the recycling system of power Battery recycling recycling, cascade utilization and recycling, and encourage the co -construction of common recycling channels.

"At present, China has registered nearly 80000 battery recycling enterprises, and the capacity of the entire industry is more than 4 million tons. Zhang Yuping said, "It should be said that the power Battery recycling has really received a lot of attention.

In 2022, governments at all levels attached great importance to the development of power Battery recycling industry, issued a series of industrial policies, further improved the construction of power Battery recycling system, and paid attention to environmental pollution and safety issues in the recycling process. "By the end of 2022, More than 10000 service outlets for power Battery recycling have been set up in the country, so as to achieve the goal of recycling nearby. Tian Yulong introduced.

It is necessary to properly utilize the battery in stages before recycling. Currently, 80% of the retired batteries can still be used, "said Zhao Weijun, Executive Director of Yuanyuan Power and President of China. A 100 megawatt energy storage power station can be directly upgraded from more than 1680 retired battery packs with a capacity of 60 kilowatt hours, which can at least allow the batteries to play an additional role for one to one and a half years, saving energy storage costs of 0.15 yuan/watt hour to 0.2 yuan/watt hour, Thus forming a certain price advantage.

Of course, it is not easy to do a good job of battery recycling and recycling. Recycling inevitably involves the recycling and dismantling of waste batteries. Zhang Yuping reluctantly stated that there are a wide variety of battery packs in various forms, and the update iteration is also fast.China claims to have more than 5000 battery packs," but these data have not been well provided to the recycling end. This forces recycling companies to do a good job in data collection to model battery packs and facilitate intelligent disassembly.

The enterprise Zhang Yuping worked for mainly engaged in waste Battery recycling recycling and other businesses. The enterprise disassembles the recycled batteries and returns them to the material supplier, forming a closed loop. They proposed the concept of full lifecycle service for lithium batteries, from providing core packaging to product development, to global recycling services, and also including safety management for cascade utilization, providing comprehensive services.

05. All solid-state and ultra fast charging are directions

In recent years, Japan, the United States, the United Kingdom, and the European Union have all proposed some national plans for power batteries. The West still needs to strengthen basic research, hoping to further advantage at the source and seize the commanding heights.Sun Shigang said that China faces fierce competition in the development of power batteries.

Faced with global challenges, high specific energy and rapid energy replenishment have become the next development direction of the power battery industry.

Wang Yu candidly stated that China's power battery industry has entered a development stage of "good or bad", but there is still a certain gap between "good bad.

According to Xiao Chengwei, the Ministry of Science and Technology has laid out four key research and development projects for high specific energy batteries, including all solid-state metal lithium batteries, new system power batteries, solid-liquid hybrid lithium-ion batteries, and all solid-state lithium-ion batteries.

"China should make efforts in strengthening basic research, so as to achieve self-reliance in science and technology from the source and hope to lead the development of the new generation of batteries. Sun Shigang believes that Solid-state batteries are the development direction of the next generation of batteries.

At present, the focus of the development of high specific energy power battery industry is the solid liquid hybrid battery and all Solid-state batteries.

Xiao Chengwei introduced that the solid-liquid hybrid battery could be produced in small batch in 2022, and the solid-liquid hybrid and all Solid-state battery could be produced in batch from 2025 to 2027, with an energy density of about 400 watt hours/kg; By 2030, The production of all solid-state batteries will be realized, and the energy density will reach 500 watt hours / kg-600 watt hours/ kg.

People have Range anxiety anxiety" about new energy vehicles

First, please LoginComment After ~