S.Korean companies establish European battery hub in Hungary

Amid the global automotive industry's shift toward electric vehicles (EVs), South Korean battery companies are increasingly using Hungary as a strategic base for their European operations. Leading firms such as Samsung SDI and SK On are strengthening localization strategies by building integrated supply chains (GSCs) that span raw material procurement, intermediate component production, cell and module manufacturing, recycling, and export.

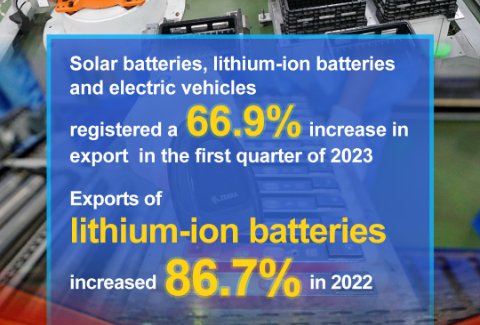

Currently, Hungary has an annual battery production capacity of around 87 GWh, which is expected to expand to 250 GWh by 2030. This would enable Hungary to meet roughly 35% of Europe’s battery demand, positioning it among the world’s top four producers after China, the U.S., and Germany.

Samsung SDI operates its plant in Göd, while SK On runs facilities in Komárom and Iváncsa, supplying batteries to major European automakers including BMW, VW, Stellantis, and Mercedes-Benz. Korean-made materials and technologies have earned high marks from European clients for their reliability and performance.

To ensure stable supply of critical raw materials such as lithium hydroxide, anhydrous hydrofluoric acid (AHF), and magnesium, Korean companies are making joint investments, operating local reprocessing facilities, and leveraging rail-based logistics. They are also developing recycling networks to comply with EU origin regulations and carbon reduction policies.

The Hungarian government has promoted battery clusters under its National Battery Strategy 2030, offering foreign direct investment (FDI) incentives including tax benefits, cash grants, and customized land. In line with the EU’s Critical Raw Materials Act (CRMA) and battery regulations, Samsung SDI and SK On are proactively adopting measures such as expanding renewable energy use, monitoring carbon emissions, and obtaining eco-certifications.

Amid fierce competition from Chinese firms such as CATL, EVE, and Sunwoda, Korean companies are strengthening technology protection through confidential core processes, local workforce training, and NDAs with partners. Joint research initiatives with Hungarian universities, research institutes, and global companies, as well as participation in EU R&D programs, aim to secure technological leadership while advancing localization strategies.

Experts note that “Korean companies’ expansion into Hungary goes beyond production growth, establishing a central role within the European battery ecosystem.” By securing supply chain stability and ESG competitiveness simultaneously, they are implementing a “glocal” strategy that blends global scale with local responsiveness.

However, ongoing challenges include navigating EU battery regulations, competition with Chinese firms on price and production, and geopolitical risks. Korean firms plan to reinforce their strategic position in Hungary by expanding local production, co-producing materials, building recycling and eco-friendly facilities, and implementing technology protection measures.

Hungary has emerged as a European launchpad for the Korean battery industry and a key axis in next-generation global value chain strategies, enabling Korean companies to strengthen competitiveness in the European market while pursuing sustainable growth.

출처 : The Korea Post(http://www.koreapost.com)

First, please LoginComment After ~